Filabot

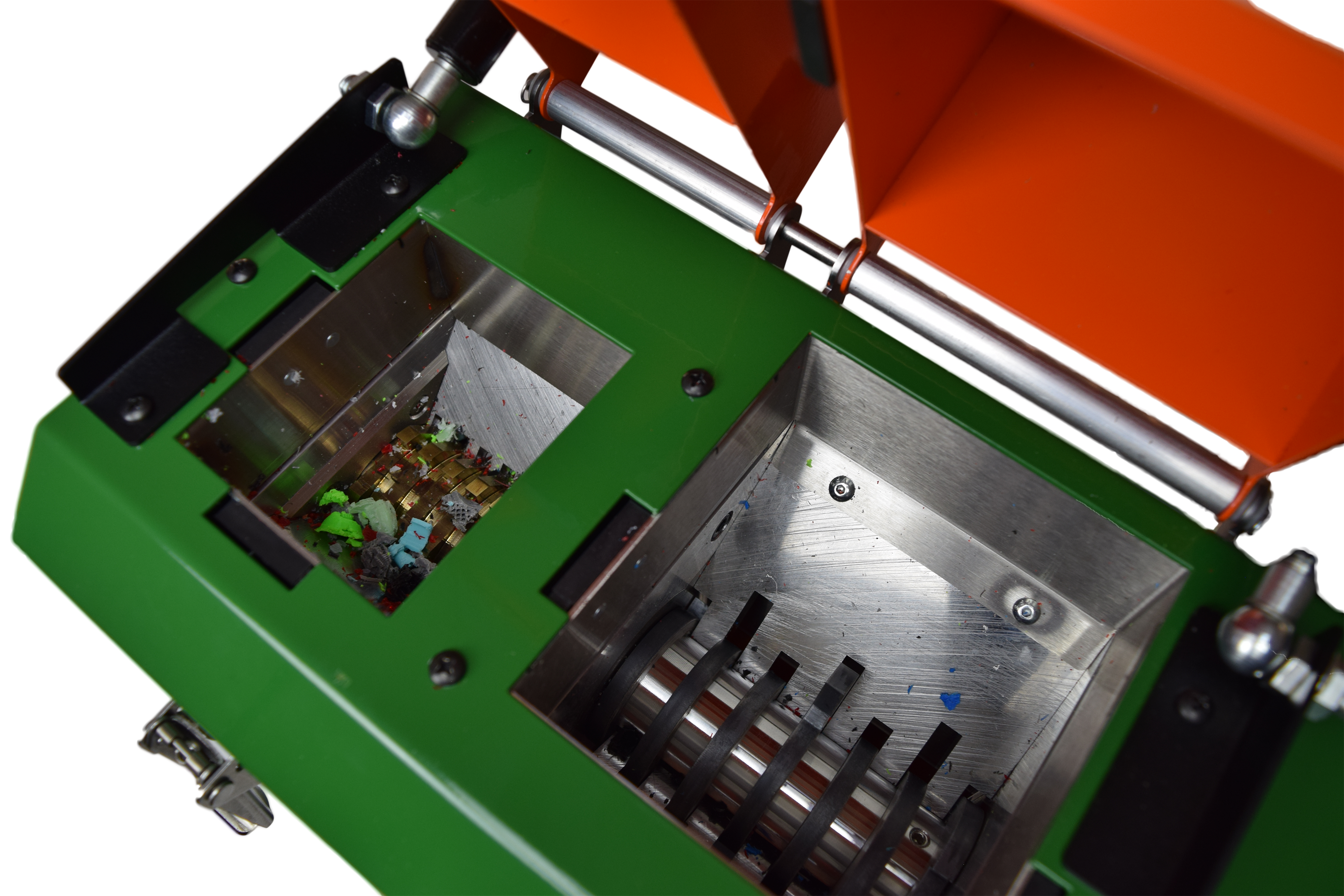

Reclaimer - Plastic Shredder

25% OFF for 2025

Use code FILABOT2025 to save 25% at checkout

Choose options

25% OFF for 2025

Use code FILABOT2025 to save 25% at checkout

25% OFF for 2025

Use code FILABOT2025 to save 25% at checkout

The Filabot Reclaimer is a granulator unit that breaks down plastic, in failed print form, waste plastics, etc. and turns that plastic into particles that can be further processed in our Filabot extruders. This unit has a two-stage breakdown process. The first stage, the Shredder, breaks down large chunks of plastics into smaller pieces, from there the broken down chunks are fed into the granulator that breaks the pieces down to the final extrudable size.

Assembly Required - The Filabot Reclaimer is shipped in three separate boxes. Assembly is required to use the unit. Two people are needed for assembly and moving. See the user manual for more details.

Recycling Process

Recycling plastic is a process that if followed correctly will produce great results. Granular material has much inconstancy in size, therefore it is not currently possible to produce high tolerance filament directly from grindings. Producing printable filament requires these steps using our Filabot hardware.

1. Grinding Plastic - Filabot Reclaimer

2. Dry Reclaimed Plastic to Remove Moisture - Can be done with an oven, desiccants, or standard polymer dryer.

3. Granular Plastic Extrusion - Filabot EX2 or Filabot EX6

4. Chopping Filament into Pellets - Filabot Pelletizer

5. Pellet Extrusion into Final Filament - Filabot EX2 or Filabot EX6

Input Connector Type: IEC 320-C14

Weight: 57kg (125 lbs) - Ships in 3 boxes

Overall Dimensions:

Shredder: Rotating Blades: 0.25” Wide A2 Hardened Steel Fixed Blades: Reversible 0.50” 4140 Steel Plate

Granulator: Rotating Drum: 0.20” x 0.20” Cutting Teeth 17-4 SS Hardened Fixed Blades: Reversible 0.50” 4140 Steel Plate. Minimum material thickness for the shredder input is about 0.030" or 0.75mm

1-Year Warranty

Currently No Videos