Introduction

At Filabot, our mission is to engineer a sustainable future by giving plastics a second life. One of the most abundant waste streams we face is PET (polyethylene terephthalate) water bottles. On the surface, recycling them into 3D printer filament seems simple: shred, melt, and extrude. In practice, the process is far more complex, influenced by material science, thermal history, and equipment design.

This technical deep dive explores both the science and the process of transforming PET bottles into 3D printing filament, based on our experience and supported by hands-on demonstrations like Dr. D-Flo’s PET recycling experiment.

The Material Science of PET

PET vs. PETG

PET is a semi-crystalline thermoplastic. Its crystallinity gives it strength and chemical resistance, but also makes it more prone to shrinkage and warping during cooling. PETG, on the other hand, is a glycol-modified version. The glycol disrupts the crystalline structure, lowering crystallinity and improving printability.

This means:

-

PET can be used for filament, but it requires tighter extrusion and print controls.

-

PET and PETG cannot be recycled together, as they have different melting behaviors.

Thermal History and Degradation

Each time PET is heated, its polymer chains shorten – reducing intrinsic viscosity (IV), which is directly correlated with molecular weight. Lower molecular weight means:

-

Reduced tensile strength.

-

Lower melt viscosity (the plastic flows too easily).

-

Potential sagging or dimensional inaccuracy during printing.

In addition, PET is hygroscopic. If moisture is present during extrusion, hydrolysis occurs: water cleaves polymer chains, accelerating degradation and creating brittle filament.

Drying Parameters

To preserve molecular weight, PET flakes or pellets should be dried at 160 °C for 4–6 hours, or until moisture content is below 50 ppm. Our Filabot Pellet Drying System is designed for this purpose.

Challenges of Recycling PET Bottles into Filament

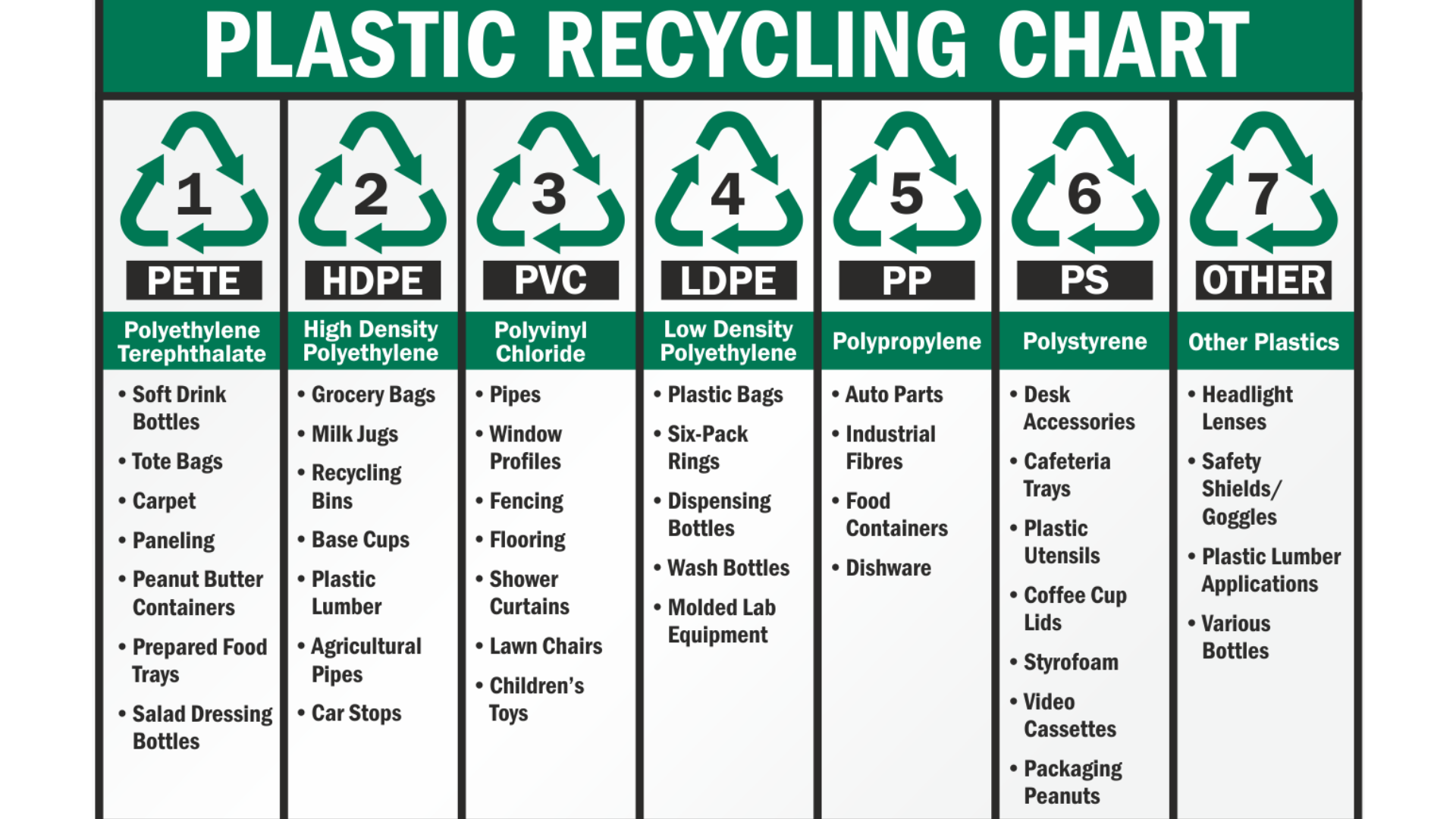

1. Contamination from Non-PET Materials

Even small amounts of other plastics (caps, labels, rings) can drastically weaken the filament. A few grams of PP or PVC mixed into PET can cause brittle, unusable filament. Industrial recyclers use spectroscopic scanners for sorting; at the lab or classroom level, this often comes down to careful manual separation.

2. Poor Shreddability of Bottles

PET bottles are thin and flexible. Unlike rigid 3D prints, they don’t “catch” well in small-scale shredders. They fold or bounce, producing uneven flakes that are harder to process downstream.

3. Low Bulk Density and Flowability

Bottle flakes have a bulk density of ~0.2–0.3 g/cm³, compared to ~0.8 g/cm³ for virgin pellets. This means hoppers feed less material per turn, causing extruder surging and starvation. Flakes also “bridge” across the hopper opening, clogging flow. Without industrial crammer feeders, operators may need to manually push flakes down.

4. Moisture Absorption

PET absorbs moisture quickly, and if processed wet, hydrolysis occurs — producing foamy, brittle filament. This makes multi-stage drying non-negotiable: after shredding and again after pelletizing.

5. Thermal Degradation from Multiple Heat Cycles

Recycled PET has already been processed once when manufactured into a bottle. Each additional melt cycle shortens polymer chains and reduces intrinsic viscosity. The solution is to blend recycled PET with virgin pellets (typically 30–50%) to restore strength and toughness.

6. Dimensional Stability in Filament Production

Cooling rate during extrusion affects PET crystallinity. Too slow, and filament becomes cloudy and brittle. Too fast, and residual stress builds up, causing warping in prints. Achieving stability requires careful control of cooling conditions.

7. Printing-Specific Issues

Even when filament is spooled successfully, printing with rPET has its own hurdles:

-

More shrinkage than PLA or PETG, leading to warping.

-

Requires higher nozzle temps (240–260 °C).

-

Very sensitive to ambient humidity in storage.

-

Even small diameter fluctuations (±0.1 mm) can lead to jams or extrusion problems.

8. Economic and Time Costs

At the desktop scale, PET recycling is not about saving money. Processing 1 kg of PET into filament can take hours of shredding, drying, extruding, pelletizing, and re-extruding. Our equipment automates much of this, but preparation and QC remain operator-intensive. The true value lies in education and sustainability, not short-term economics.

Processing PET Bottles into Filament

Step 1 – Shredding

PET bottles are thin-walled and flexible, which makes them challenging to shred with small-scale equipment. The Filabot Reclaimer is designed for rigid 3D print waste up to 3 inches in size. To process bottles:

-

Pre-cut or flatten bottles to fit the hopper.

-

Remove caps, rings, and labels (these are PP or PVC).

-

Run through the Reclaimer’s shredder and granulator stages to achieve ~3–4 mm granules.

At this stage, particle shape and size distribution matter. PET flakes often have poor flowability. In angle-of-repose tests, virgin PET pellets spread freely (<45°), while PET flakes stack steeply (>80°), indicating poor feeding characteristics.

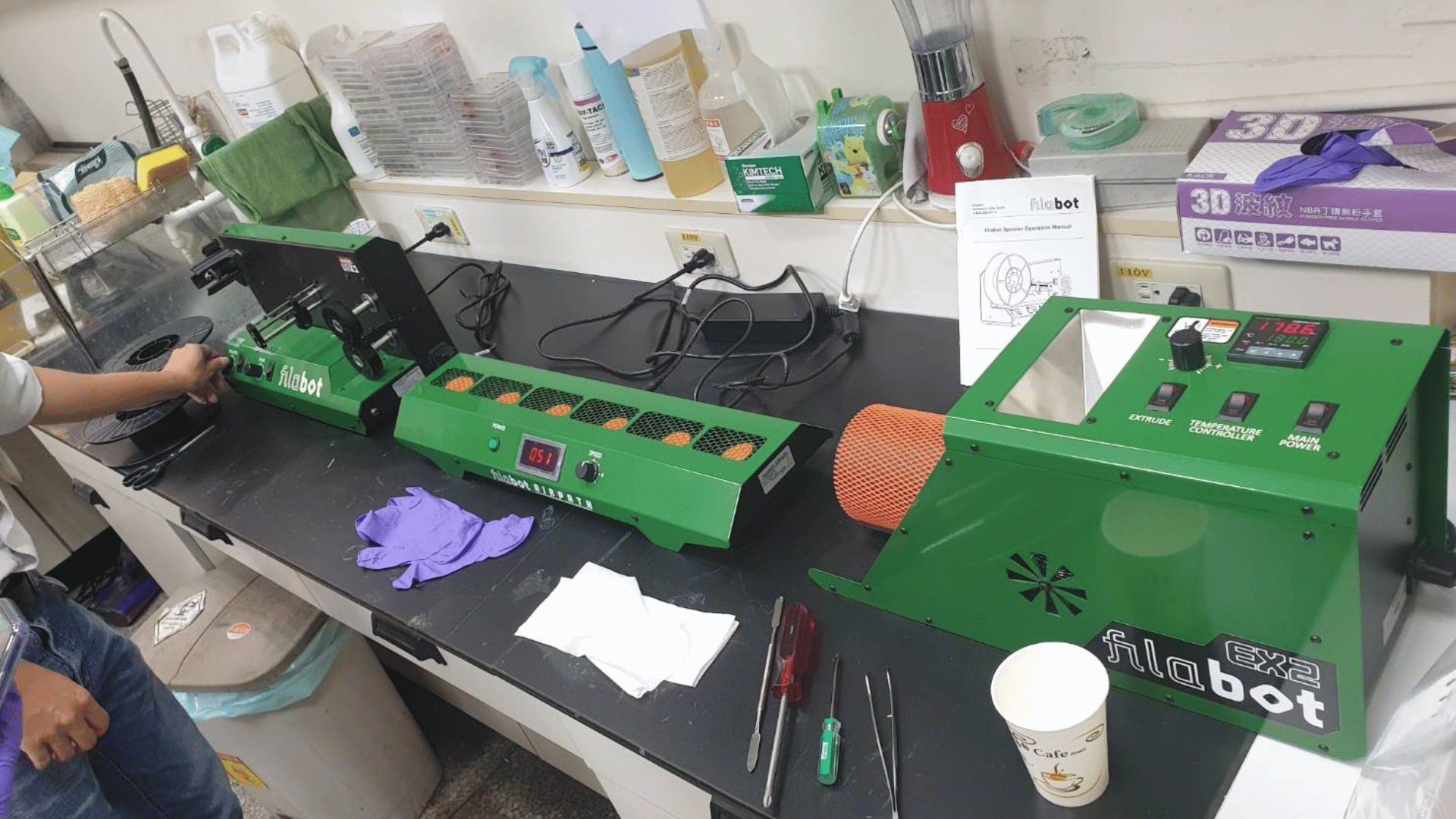

Step 2 – First Extrusion (Thick Strand)

Directly extruding flakes leads to inconsistent feeding, so we recommend an intermediate step:

-

Load granules into a Filabot Extruder.

-

Fit a 3 mm nozzle and extrude slowly.

-

Output is a thick strand (“noodle”) that consolidates irregular flakes into uniform material.

This step stabilizes flow and reduces the chance of clogging.

Step 3 – Pelletizing

The thick strand is then chopped into pellets using the Filabot Pelletizer. By adjusting feed and cutter speed, pellets can be sized ~3 mm long, closely resembling virgin resin. Pellets solve two problems:

-

Flowability: Pellets flow uniformly into the hopper.

-

Bulk density: Pellets pack consistently, preventing extruder surging or starvation.

Step 4 – Final Extrusion & Spooling

Pellets are dried again, then extruded with a standard 1.75 mm nozzle:

-

Extrusion temp: 250–265 °C.

-

Slow screw speed to minimize viscous heating.

-

Spooling controlled by the Filabot Spooler.

-

For quality control, the Filameasure monitors diameter in real time.

For best mechanical properties, we recommend mixing 50% recycled pellets with 50% virgin PET. This blend offsets thermal degradation while keeping the sustainability advantage.

Quality Control Considerations

For researchers and labs, rPET filament can be evaluated using:

-

Diameter tolerance: ±0.05 mm is ideal for reliable printing.

-

Tensile strength: Compared against virgin PET or PETG to quantify mechanical loss.

-

Melt Flow Index (MFI): Indicates how degradation has reduced viscosity.

-

Moisture content: <50 ppm before extrusion.

These metrics ensure reproducibility and provide valuable data for sustainability research.

Industrial vs. Filabot Scale

Large-scale PET recyclers employ:

-

Grooved barrel extruders to increase friction with flakes.

-

Crammer feeders or side screws for poor-flowing materials.

-

Vacuum venting to remove moisture during extrusion.

Our modular Filabot system mirrors these principles at a desktop scale. By breaking the process into stages – shredding, pelletizing, extruding – we deliver reliable results on standard 110 V power.

Printing with rPET Filament

Printing settings differ slightly from PETG:

-

Nozzle: 240–260 °C

-

Bed: 75–90 °C

-

Enclosure: Recommended for larger prints

-

Layer adhesion: Excellent when dry, poor if moisture is present

Expect minimal odor, strong layer bonding, and higher toughness than PLA. Warping is possible on large flat parts, so an enclosure or brim is helpful.

Conclusion

Recycling PET bottles into filament is more than an environmental gesture – it’s a technical challenge that combines polymer science, process engineering, and quality control.

With the Filabot Reclaimer, Extruder, Pelletizer, and Spooler, labs and classrooms can replicate industrial recycling workflows at the desktop scale. The result is high-quality rPET filament – and a tangible way to teach, research, and demonstrate sustainability in action.

Instead of a one-way trip to the landfill, yesterday’s water bottle becomes tomorrow’s 3D-printed innovation.