Filabot

EX2 Extruder Setup

Choose options

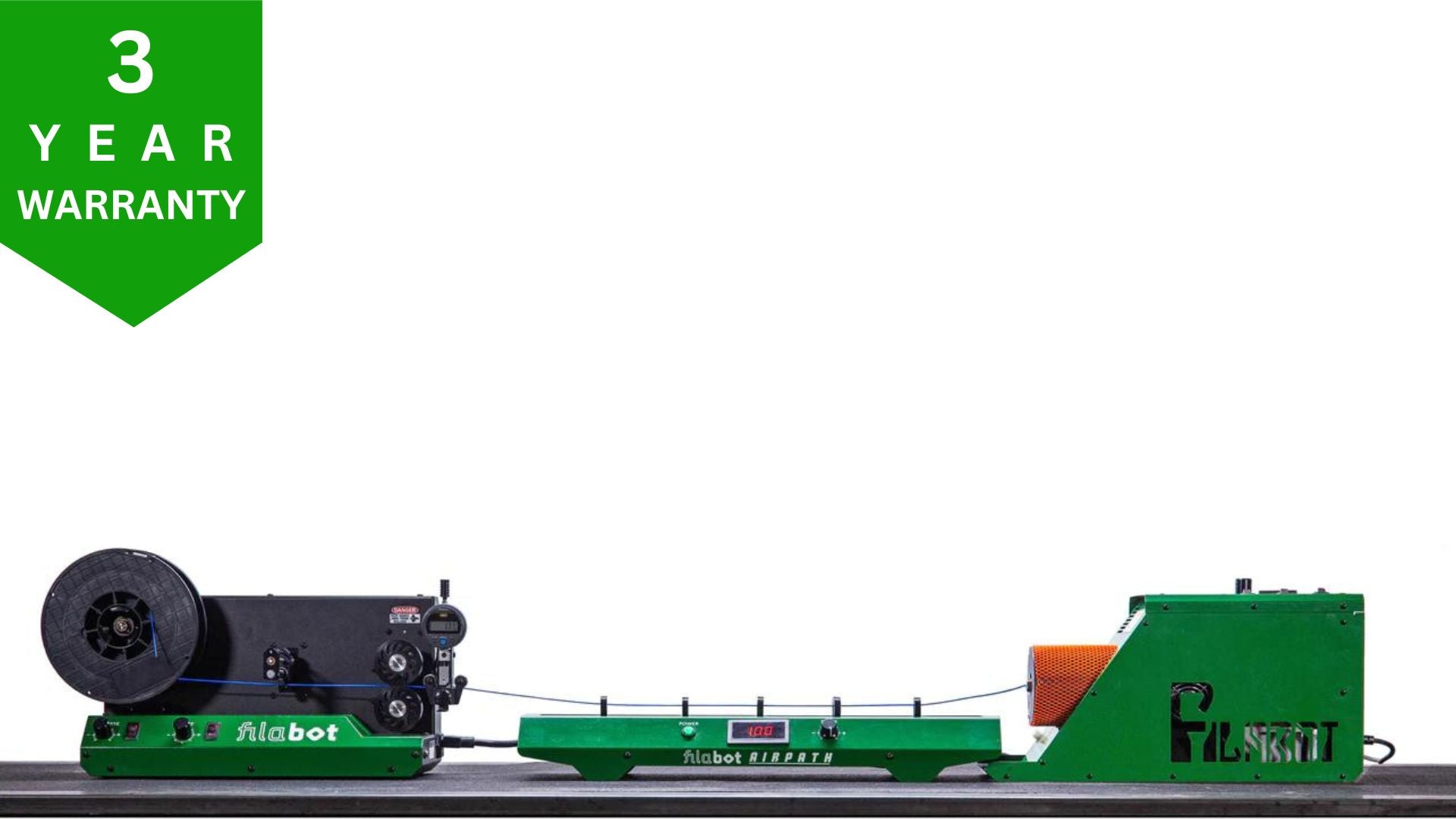

The EX2 Extruder Setup is a material conversion tool that opens new opportunities in 3D printing by enabling efficient plastic recycling and innovative use of plastics. It provides a small-scale solution to a significant environmental challenge, making sustainable manufacturing accessible to a broader audience, including those without expert knowledge. This closed-loop system exemplifies sophisticated engineering, condensing an entire filament production line into three key components: the EX2 Extruder, Airpath, and Spooler. This comprehensive bundle includes everything needed to develop and produce filament for any FDM or FFF 3D printer and comes with a 3-year warranty.

EX2 Extruder

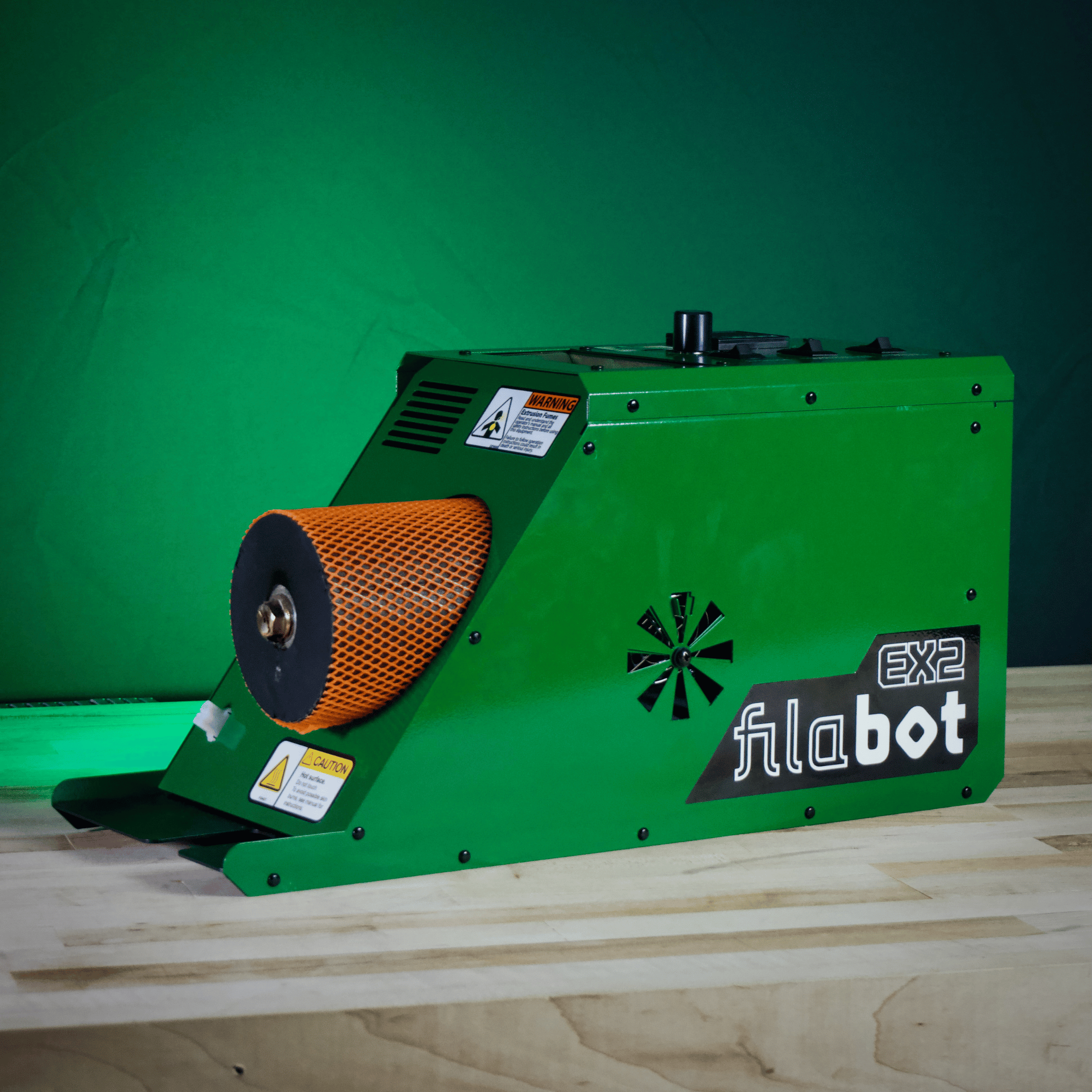

The EX2 Extruder is our entry-level extrusion system, designed to be user-friendly for those new to filament making. It features a compact three-stage extrusion screw made from hardened and polished high-carbon stainless steel. This proprietary, patent-pending screw pressurizes plastic during extrusion, aiding in diameter control and enhancing overall output. The screw's mixing capability is optimized with a progressive compression section that applies shear force between the polymer and the barrel wall. The EX2 also includes extrusion speed control, with a speed control board featuring an automatic, variable voltage control module engineered to regulate the precise RPM of the screw as forces fluctuate during the extrusion process. When paired with the Spooler, the system achieves tolerances of +/-0.05mm at a rate of 2 lbs per hour.

Airpath

The Airpath uses forced convection to cool filament as it is being extruded. The Spooler can be used for the common materials to help get greater tolerance and easier extrusion. The air path is a must for researchers and development labs who are working with higher temperature polymers where the filament needs to be cooled before it is passed through the Spooler. This system has a speed readout so that consistent speeds can be set.

Spooler

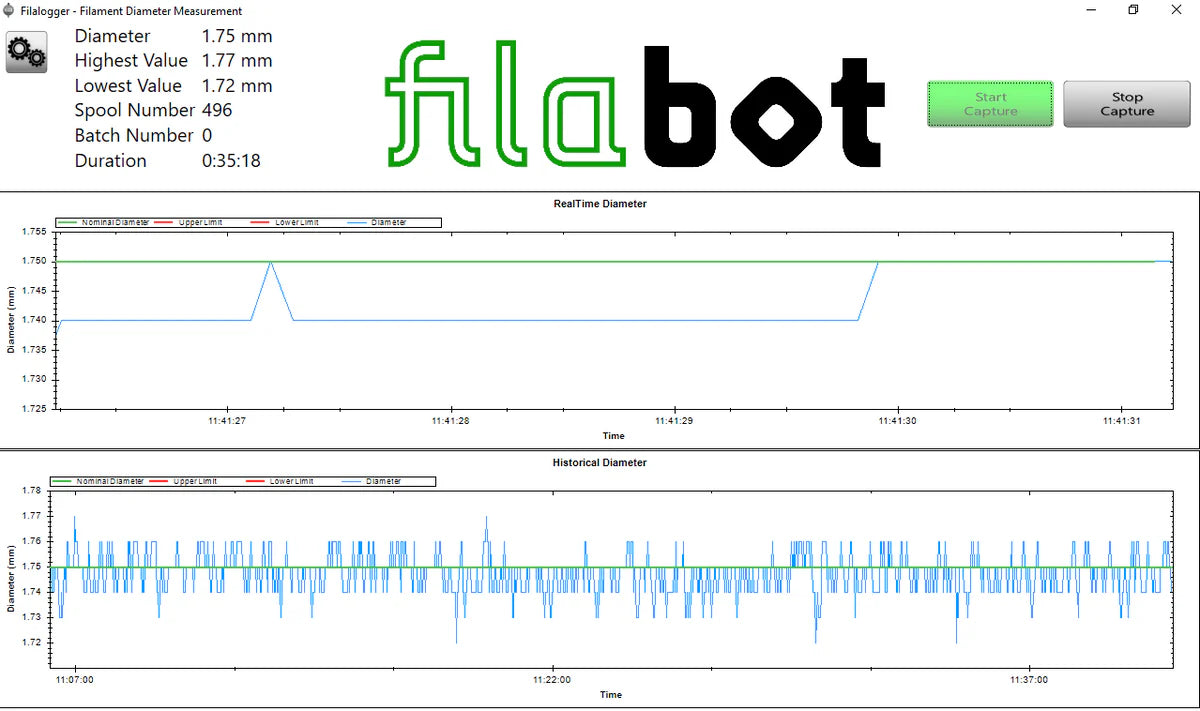

The Spooler is the ultimate compliment to our extruder systems. In addition to conveniently spooling your extruded filament, the unit allows you to easily fine-tune the extrusion diameter for the tightest possible tolerances. This is achieved by adjusting the speed of the puller wheels, which draw the filament from the extruder. This updated model features a variable traverse mechanism to evenly distribute filament onto the spool, an upgraded circuit board for the smoothest possible power delivery, and stainless roller shafts which glide on sealed bearings. Also included is the Filameasure and accompanying software for logging and graphical visitation of the extruded filament.

Bundle Includes

- 1 - EX2 Extruder

- 1 - Airpath

- 1 - Spooler

- 1 - Filameasure

EX2 Includes

- 1 - 2.85mm Nozzle

- 1 - 1.75mm Nozzle

- 1 - User Manual

- 1 - Power Cord

- 1 - Packet of Anti-Seize

- 1 - Package of Purge

Typical measured power consumption, which will vary, for different polymers it's 190 Watts for the EX2 Bundle.

Extrudable Plastics: ABS, ABS Flame Retardant, 4043D PLA, 3D850 PLA, 3D870 PLA, PC, HIPS, PETG, and WAX. Lower Melt Flow Polymers

Extrusion Rate: Over 2 lbs (0.91kg) of filament per hour (About 250 inches per minute using 4043D PLA @ 1.75mm)

Filament Sizes: 1.75mm and 2.85mm Material Input Size: 1/8in (3.18mm) pellets to powder.

Material Capacity: Hopper Volume - approximately 26 cubic inches (426.1 cubic cm)

Screw Void: 1.75 cubic inches (28.8 cubic cm)

Temperature Control: PID Controller, One Zone

Feed Screw and Drive: 0-35rpm Speed Control 85in lbs (9.6 Nm) drive force General Purpose Custom Designed Feed Screw Non- Removable Screw Dimensions: OD: 5/8" L/D ratio: 12 Pitch: 1/2" Compression: 2.5:1

Universal Power Input (For the EX2): 110 VAC or 220 VAC - 50 to 60hz - 500 watts

Physical Characteristics: Weight 28 lbs (12.7kg) and dimensions of 18in x 7in x 9in (45.75cm x 17.78cm x 22.86cm)

Full 3 Year Warranty

**Voltage Note - the 110VAC or 220VAC specific to the country that you are going to be using the extruder system in. There is no operational difference between the 110VAC or 220VAC.**

![]()

EX2 Extruder Overview Video

Airpath Overview Video

Spooler Overview Video