As unlikely as it may seem, there is finally a material that not only has improved stability but actually helps absorb CO2 from the environment, called the ecoPLAS 3D201 from REearthable.

ecoPLAS is a manufacturing-ready biodegradable and compostable limestone (CaCO3) compound with PLA LX175 base that conforms to the FDA food contact safe (G.R.A.S.) specification (and many others) and is suitable for 3D Printing and Injection Molding.

Limestone, which is primarily calcite (CacO3) sequesters CO2 during formation and doesn’t release it unless heated above 1500˚ F. Its natural color is off-white, though ecoPLAS can be dyed to a range of colors and is used as material for additive manufacturing or as pellets for injection molding. No special equipment or conditioning is required to put this material in service.

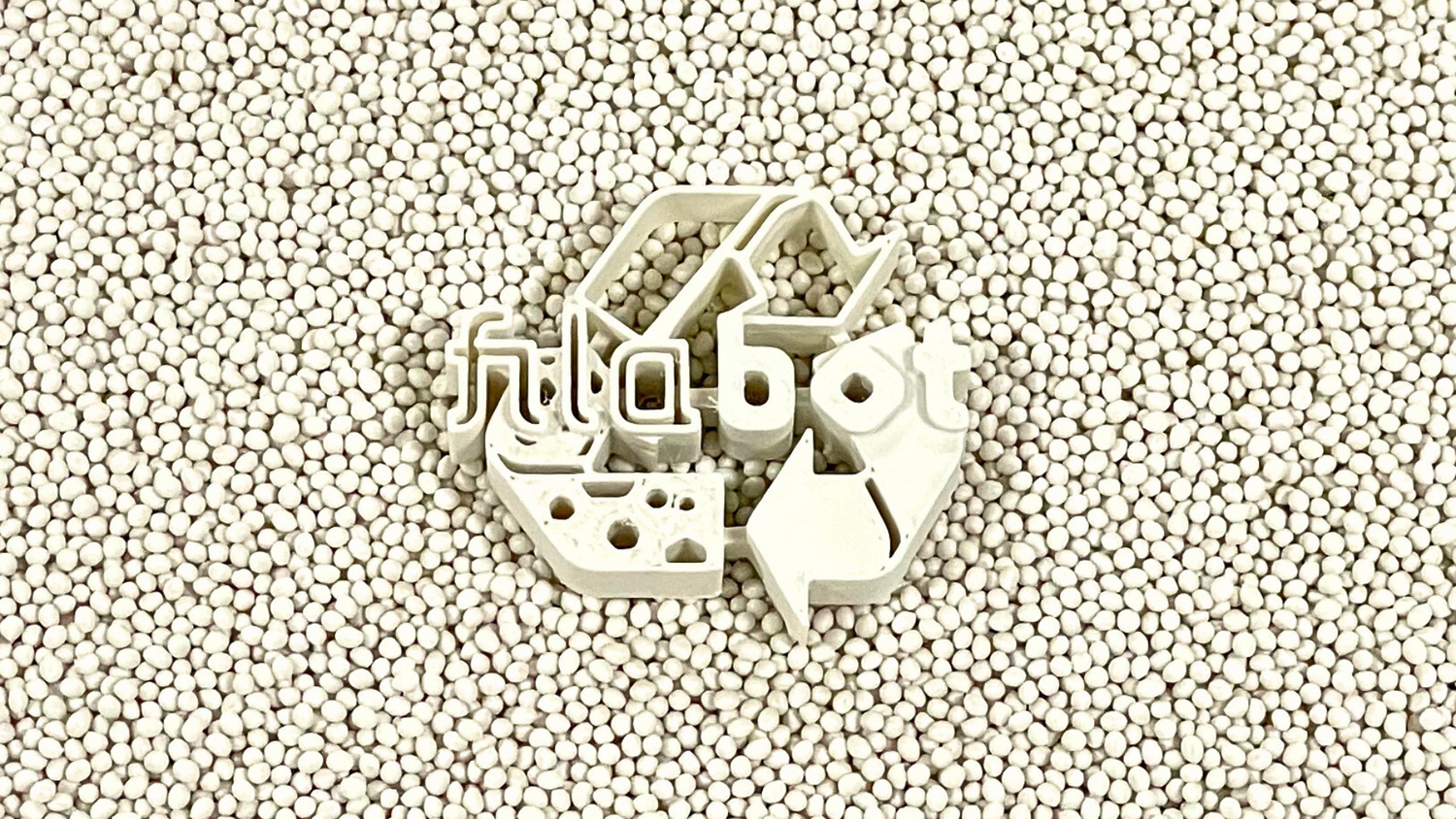

Check out the test patterns we ran using ecoPLAS and compare them to other materials. The limestone base gives it a nice surface finish and precise outlines of complex shapes.

Pictured clockwise from the top:

- Top: ecoPLAS 3D201

- Right: Recycled Toothbrushes

- Bottom: Recycled CDs

- Left: PLA