We are proud to announce that the Filabot Pelletizer is now available. This machine will help work towards our mission of providing equipment that allows closed-loop recycling of plastics.

The Filabot Pelletizer efficiently recycles your scrap, failed, partial, and incomplete filament segments. Allowing you to consolidate large volume, loose filaments to easily storable and sealable containers of pellets.

Built for a long trouble-free life from robust milled components and easily serviced and cleaned hardware. High-speed filament chopping has never been so easy. The hardened rotating blade assembly makes over 200 slices per second allowing feed speeds exceeding those of human hands or our own filabot spooler at max speed, both of which are options. Feed scrap filament down to 2.5cm length and as low as 1mm in diameterby hand or directly link the pelletizer with Spooler using the included quick-release tubing to intake spooled or directly extruded filament.

PLEASE NOTE:

- Universal power available in 110 and 220.

- If you are looking for international shipping please contact us at contact@filabot.com

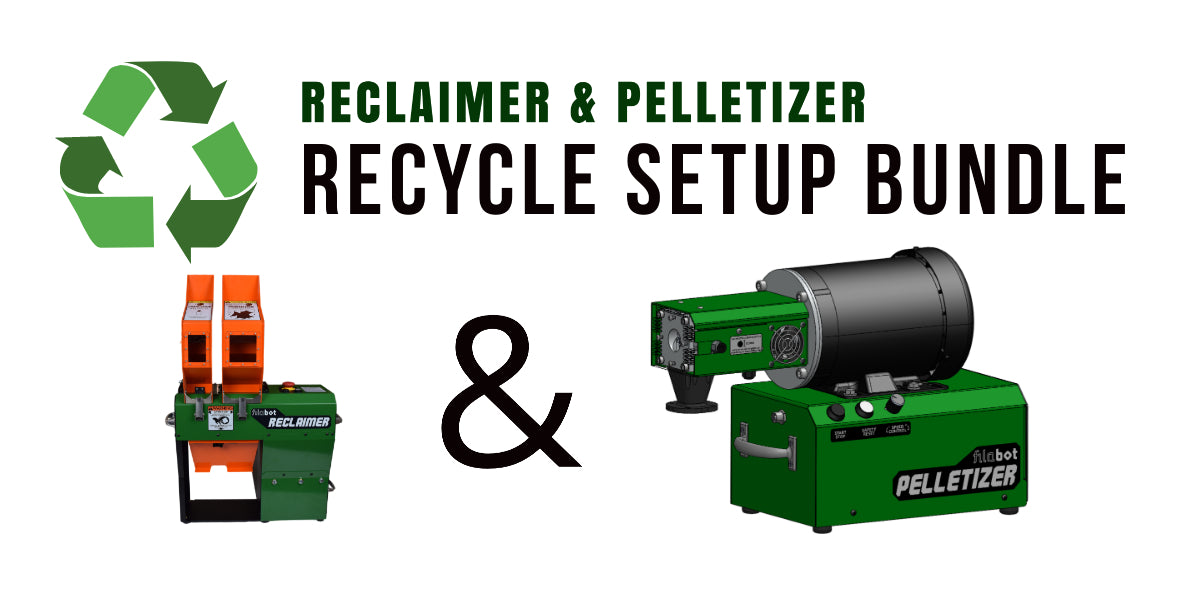

Consider the Reclaimer/ Pelletizer Recycling Setup bundle.

Consider the Reclaimer/ Pelletizer Recycling Setup bundle.

The Filabot Reclaimer is a two-stage shredder and granulator unit designed to break down plastic into a size compatible with Filabot extruders. The shredder “Stage 1” breaks down larger plastic chunks into a size that can be loaded into the granulator “Stage 2” for final size reduction. This two-stage approach improves the versatility of the Reclaimer for use with a variety of material types and shapes which may break down differently, allowing the user more control over the final output. The Filabot Reclaimer also includes a smart control system that provides for maximum safety.

For the bundled Recycling Setup click here

Together this hardware is used in the recycling process to turn plastic and failed prints into new filament. This is the process that we have verified with our hardware:

- Break down plastics using the Filabot Reclaimer

- Dry granulations

- Regrind extrusion of granulations

- Filament pelletizing using the Filabot Pelletizer

- Final production filament extrusion