3D prints capable of shielding radiation? It's not science fiction, it's just science- compound polymers created with ABS extruded with bismuth and PVDF!

As an emerging technological field, 3D printing continues to expand its capabilities at a rapid pace. Many of these novel innovations are made specifically in the category of materials. While there are entirely new materials being extruded each year, in spring of 2020 scientists at the Los Alamos National Laboratory in New Mexico focused their research on making modifications to a tried-and-true plastic in the field of 3D printing - ABS.

Though now superseded in overall popularity by PLA, acrylonitrile butadiene styrene is a go-to solution for prints requiring superior mechanical strength and impact resistance. The researchers at Los Alamos hoped to take this durability a step further through the addition of concentrations of bismuth (Bi) and polyvinylidene fluoride (PVDF). Bismuth is a chemical element that is a post-transition metal. A solid at room temperature, it has similar properties to lead in that is quite heavy but has a low melting point. It melts around 270 C - a quality that allows it to be combined with ABS and run through an extruder, creating a polymer capable of shielding gamma radiation. PVDF is a hydrophobic polymer that has high chemical resistance, which can slow the decay of ABS when subjected to organic solvents.

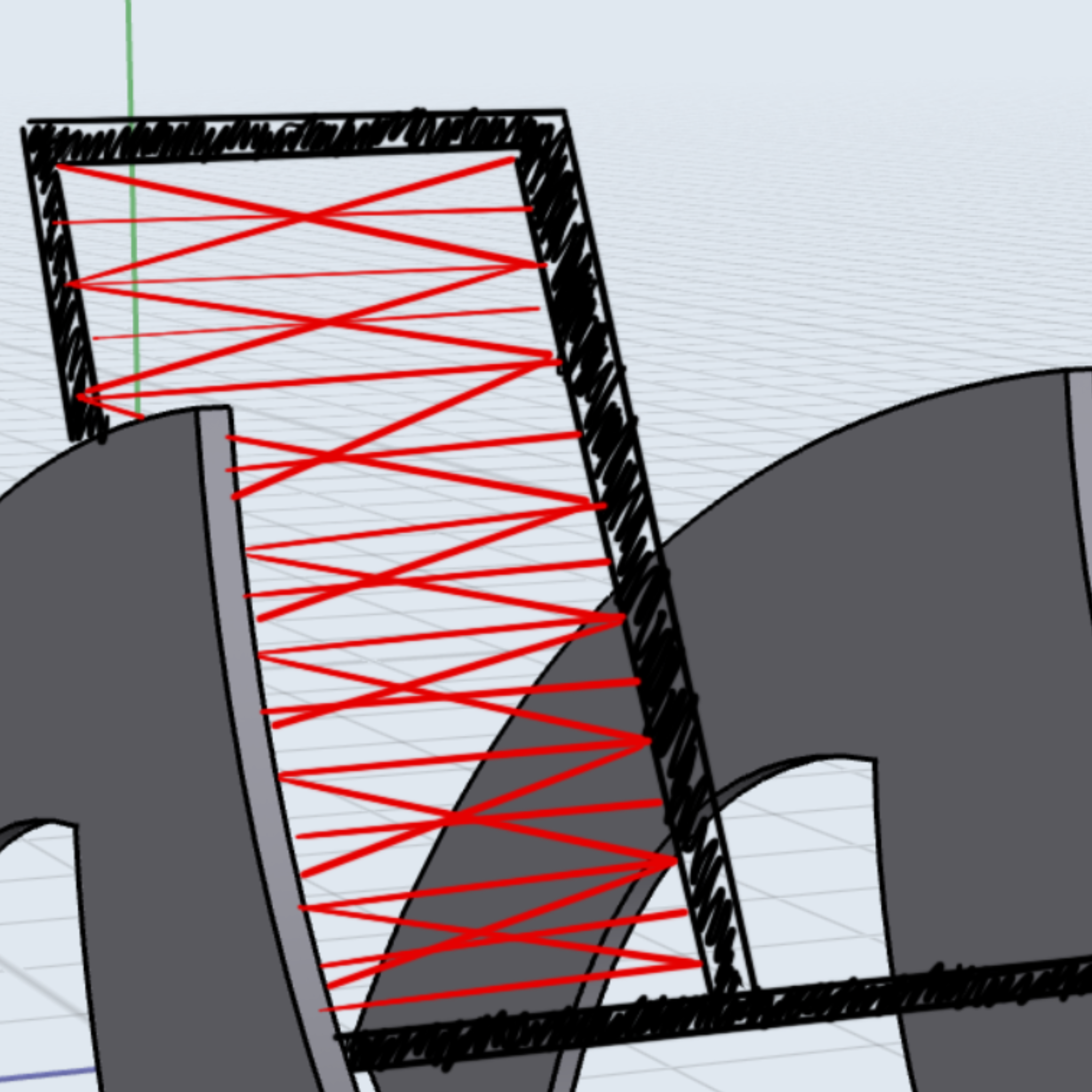

The researchers at Los Alamos National Laboratory introduced various concentrations of Bi and PVDF to ABS by dissolving the ABS in acetone and mixing in the additional constituents. Once this mixture was allowed to harden again, it was chopped into 1 cm square pieces and extruded through a Filabot EX2, the resulting filament was then gravity fed through a water bath. Polymer composites consisted of up to 66% Bi by weight and up to 25% PVDF by weight - these filaments were printed into material blocks which could be subjected to various tests of mechanical strength, resistance to organic solvents, and shielding capabilities when subjected to gamma radiation.

Radiation attenuation data showed that the test blocks were capable of shielding gamma rays, though the effectiveness was variable depending on density and porosity of the printed object. A block 6 cm thick was required to shield 50% of gamma rays. This is comparable to a 0.5 cm block of pure lead. Equally importantly, after being irradiated the polymer showed no signs of degradation. Resistance to organic solvents was tested via suspension of filament in xylene, toluene, and chloroform - all of which readily dissolve basic ABS. The mixture of ABS/Bi/PVDF, while it did break down in the solvents, took twice as long to degrade as basic ABS - showing that the mixture would have greater chemical resistance in harsh settings where these solvents were present. The addition of Bi and PVDF filler did affect mechanical properties of the filament, for example, thermal stability was decreased after addition of Bi and PVDF filler and maximum mechanical stress was reduced as well. However, none of the impacts were significant enough to overshadow the successful enhancements of the ABS for specialized applications.

Though the breakthroughs at Los Alamos National Laboratory pertain to very particular material combinations and aim at specific goals, the implications for the world of 3D printing are myriad and long-reaching. As explorations into polymer composites continue, the possibilities will continue to expand, increasing an already immensely versatile field of technology.

SOURCES:Brounstein, Z., Talley, S., Dumont, J., Zhao, J., Lee, K., & Labouriau, A. (2020). Fused filament fabrication of polymer composites for extreme environments. Journal of Materials Research, 35(12), 1493-1503. doi:10.1557/jmr.2020.118