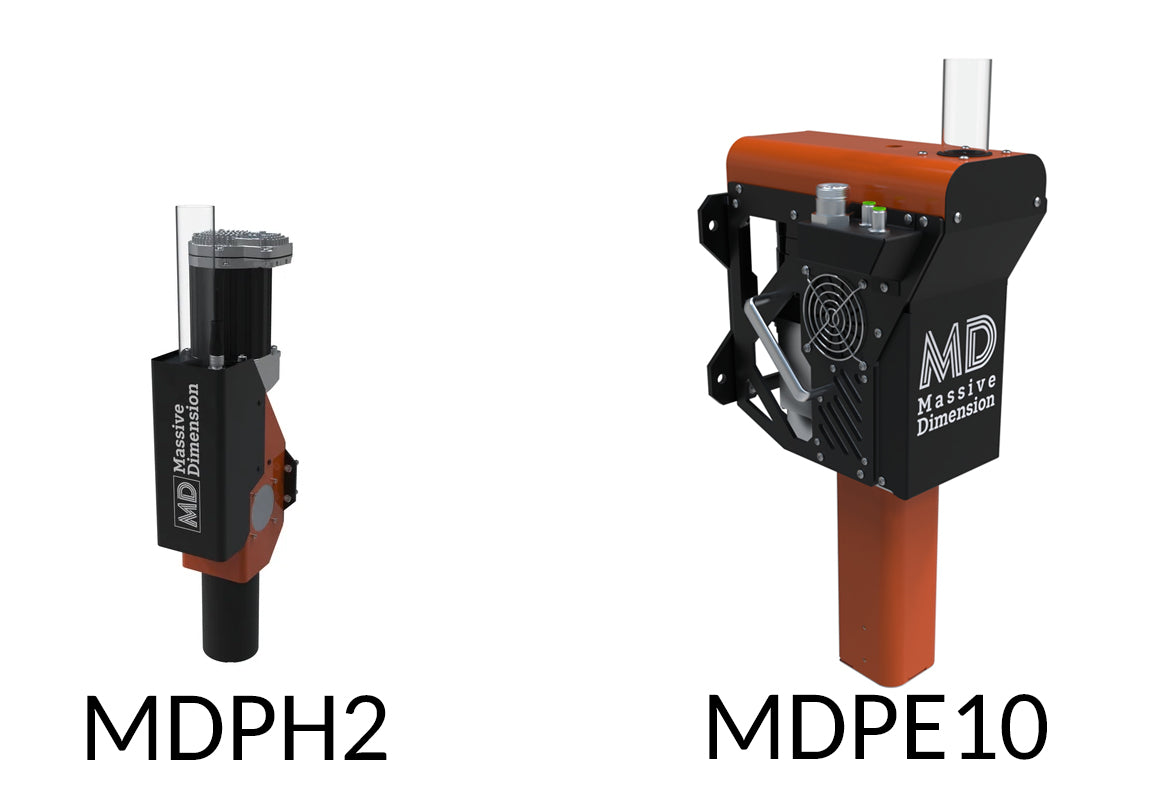

Massive Dimension is excited to introduce our latest direct print extruder head to the world- the MDPE10! We’ve built upon the proven platform of the MDPH2 using all of the experience we’ve gained working in the frontier of large format printing over the past two years. The new MDPE10 comes equipped with features designed to free the user from constraints and limitations on their 3D printing capabilities. Click here to view the product listing. In stock and shipping now!

More power: 1000 watts for the drive motor as well as 1000 watts of heating power for the heat zones. This translates to greater output- the MDPE10 can extrude up to 10 lbs per hour, five times more material than the MDPH2. Greater output in turn means faster prints as well as the ability to print with larger diameter nozzles, allowing for greater line widths in a single pass.

Quadruple the heat zones, individually controllable with their own PIDs. This enables the extruder to work with a wider range of polymers that require fine tuning of their melt point for ideal flow rate. A longer, hot swappable screw with a 24:1 L\D ratio with five different variations to choose from to meet the demand of any polymer.

Swapping out screws has been made even easier. The new design offsets the gear drive to the side of the screw which allows the screw to be accessible from the top of the print head enclosure- to remove the screw simply unthread the nozzle and give the end a few taps to unseat it and drop it down from the barrel. Screw replacement is also made easier through this design- each extruder ships with a magnetic holder that can be placed on top of the enclosure to keep the screw in place once it is put into the barrel while the nozzle is threaded back on. No more fighting gravity or dropping screws!

Versatility in customization: The barrel enclosure features two different mounting points close to the hotend to allow easy integration of your preferred accessories such as Z-probes, print fans, or even cameras to monitor your prints remotely! A flip down panel on the main body of the extruder allows instant access to DIN rails for necessary wiring of accessories, and there is an auxiliary M8 port on the top of the enclosure for quickly connecting other add-ons.

The feed tube is accessible through the top of the enclosure and has screws for securely mounting a variety of hoppers. This tube has a 30 degree angle of repose and the diameter has increased from 5/8” on the MDPH2 to 1” for the new MDPE10.

All of these parts work together to create an extruder that can meet the demands of high output, fast paced production with a wide range of polymers. Rapid prototype with prints finished mere hours after you model them. Print bigger- paired with a large enough movement system the MDPE10 is capable of printing furniture, such as tables and chairs. Save time and money and increase your level of automation printing directly from pellets instead of filament.

Material Testing Service

Our in-house materials testing lab has run numerous output tests on a range of common polymers such as ABS, PLA, HIPS, and PETG, with a variety of fills and additives such as wood dust and carbon fiber. We continue to add to this list as time goes on and are enthusiastic about developing material extrusion knowledge in the field. We offer an ongoing service to clients who are interested in utilizing experimental polymers for additive manufacturing but do not possess an extruder- simply send us the material in question and we will test it on our machines. The testing fee can be credited towards the purchase of a print head such as the MDPE10.

Extruder Exchange Program

We value our supporters who have invested in our product line and would like to continue to develop and innovate along with us. For this reason, Massive Dimension is currently offering an exchange program for customers who bought an MDPH2 and would like to upgrade to the new MDPE10. If you would like to trade in your current machine for credit towards a new one, please contact us at contact@filabot.com for details on making the switch!

The horizon that 3D printing technology is moving towards is growing larger. What will you choose to print when you are free to print anything?